Our Process

Shoring Basics

Shoring is something that not a lot of people know about, but when it is required, there’s no way around it whether for a residential or commercial project. So how does shoring work?

For those of us who may be new to this process, we’ll run through the basics, so you understand why it’s important to select the right shoring company.

What is shoring and why do I need it?

By definition, ‘shoring’ is the act of supporting or holding up something that is weak, unstable, or susceptible to movement.

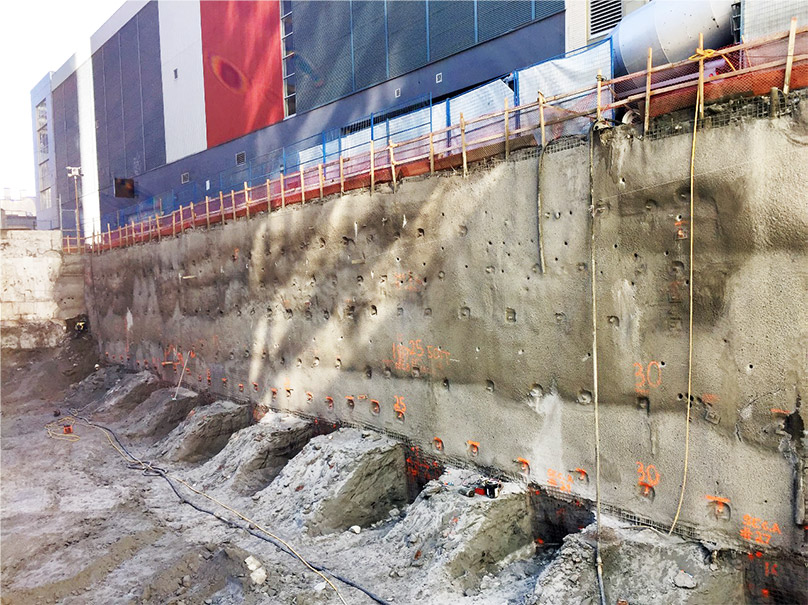

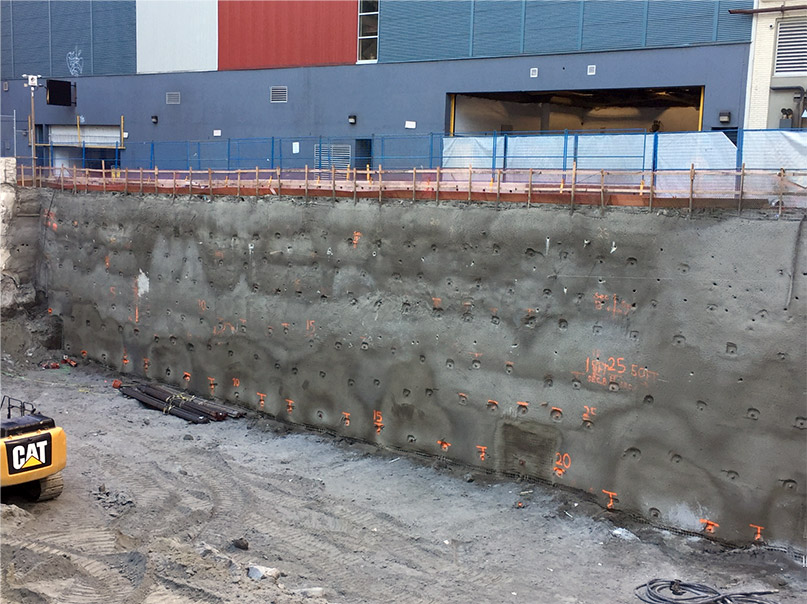

Shotcrete shoring usually involves a combination of shotcrete (sprayed concrete) placement for soil retention, strength and reinforcement, anchor drilling and anchor installation to hold the shotcrete in place.

Many construction projects, such as hillside projects or deep parkades, require shoring because soil will collapse into the site if not supported properly during the excavation. Think of trying to dig a hole in loose sand. It often fills right back up if you don’t have something to support the perimeter.

Shoring secures the perimeter walls of the excavation site. This ensures the safety of all construction workers, while also maximizing the building footprint size. Shoring also retains the structural integrity of the excavated site, so it doesn’t affect neighbouring buildings and civil infrastructure.

That’s why many large construction projects, such as home-building or apartment buildings, require some type of shoring. The alternative is a sloped excavation. However, urban areas typically cannot support this due to parkade size requirements and property line constraints.

What to Expect

Excellent Communication

Our personal service relies on ongoing communication between the client and our team of experts. Our experienced project managers keep you up to date throughout the entire process. That’s how we keep on-schedule. That also means we communicate if a job requires more complex solutions, if there’s a recommendation that will help achieve better results or a solution to a challenge you may be facing.

Safety

We make safety our top priority. We have an excellent safety record and never compromise on safety protocols. We comply with all WorkSafeBC standards. While on the job, we adhere to all design and engineering recommendations and only use proper installation methods. To ensure an ongoing, safe work environment for our employees, we conduct a monthly safety meeting and ensure that all our employees are WHMIS trained. We also perform daily onsite checks, such as a toolbox safety meeting, inspection of machines and equipment along with job-specific, specialised training for our drilling and nozzlemen.

Professional Project Management

From our project estimators to our crew, foreman and project managers, all of them have years of experience in their field. Our supervisors are all highly qualified in professional project management and you’ll know the difference once you start to work with us. We’re not only excellent problem-solvers, but most of our employees have years of practical, on the job experience, which makes us uniquely qualified to handle even the most difficult jobs. If problems occur, they find efficient, cost-saving ways to quickly resolve the problem, such as re-arranging schedules to meet client needs, or offering one on one consultations to resolve any issues.

Quality

Using the best equipment and staff, we focus on delivering the highest quality products at the fairest prices. We also believe that quality means reliability, timeliness and commitment to service and satisfaction. We always deliver and we stand by our service. We make sure that it’s done right the first time, with minimal, if any, redoing of work. If any extras are needed, we always require a field “sign off” by the client, before we do any work. We even close a job with an “as-built” site drawing if necessary, to ensure consistent quality and a record of the work done.

Simplicity

A new construction project can be complex enough, so we make it easy to get started with accurate and simple quotations. During a project, we offer simple, monthly progress invoicing that itemizes all expenses and costs, so there are no surprises when it comes to staying on budget.

The Shoring Process –

Step by Step

How exactly does shoring work?

Depending on the project, it can get complicated.

And depending on your exact project requirements and restrictions, the shoring process may vary.

Assessing Shoring Requirements

First thing’s first, you’ve got to assess what type of shoring is required and while we can’t assist with the design process, there are many fantastic geotechnical engineers in the lower mainland who can help guide our customers to determine what type of shoring will be required.

There’s Soil Nailing…

Soil nailing is one of our specialities and it’s a great method of earth retention that allows you to maximize every inch of a site. In soil nailing, we construct massive vertical walls of sprayed shotcrete that are supported with horizontally grouted soil anchors that hold everything up.

Here’s how it typically works…

Our crews alternate between anchor drilling and shotcrete shooting to secure small “panels” of soil until we reach the bottom of the hole. Our crews strictly follow whatever shoring sequence is required by the project engineer to ensure the continuous safety and integrity of the wall, soil, and neighbouring structures. When the shoring wall is complete, the excavation contractor completes the interior excavation so that the footings, building walls, and crane pads can go in next.

This shoring method also allows you to design a building’s foundational wall mere feet away from each property line, which can be advantageous if you’re building in space-restricted, highly dense urban areas.

Then, there’s Non-Encroachment Shoring…

Sometimes, an agreement cannot be reached with neighbours when it comes to the encroachment of soil nails. In this case, the excavation needs to be supported vertically, using cantilever piles with a maximum wall height of ten feet.

Or, for deeper requirements, the excavation needs to be supported internally, using a Raker system of angled steel beams, welded to more solid vertical piles and Waler beams, pictured here. For stability, the Rakers are grounded in a concrete strip footing, often secured with its own soil anchor system.

Here’s how a typical shoring sequence will go…

Step One: Drill the Anchors

For the purposes of this example, we’re going to go with the soil nailing shoring, which is the most typical and cost-effective construction choice.

Step Two:

Prepare and shoot the first set of soil panels.

Before we can begin to spray the shotcrete, the excavation company will vertically dig out every 3rd panel (or what is approved by the engineer based on ground conditions) from the berm we just drilled through – please see below.

Step Three:

Prepare and shoot the second set of panels

The next day, the excavation company will repeat the same procedure.

Step four:

Prepare and shoot the last remaining panels

The following day, the excavation company will vertically dig out the last 3rd of the remaining panels.

As you can see, each part of the anchor drilling/shotcrete shoring process requires a minimum of one production day to let the concrete and/or grout set before moving on. This means that even small jobs can take a minimum of 4 days per 5 to 7 feet of vertical wall.

And with even the best technique, there can be some unforeseen ground issues, especially in the Greater Vancouver area. That’s why you need an experienced crew and foreman to assess the site, the shoring requirements, soil conditions, and to properly and reliably install the anchors and shotcrete. With over 200 years of collective experience in the construction industry, our Power Shotcrete team can help you navigate through any challenge.

Our Process for

Complex Requirements

With our thorough process, we take every precaution to ensure the highest quality results. But sometimes a shoring project doesn’t go as planned. Because soil is unpredictable, any job can go from simple to complex. That’s why it’s important to work with experienced geotechnical construction servicemen. When things get tricky, that’s when you need the experts.

Working in Soil –

What Can Happen

What can make a project more difficult?

Even with borehole and soil reports, ground conditions can vary wildly across a site especially with the glacial settlement we see here in the lower mainland. Poor soil conditions can cause wall sluffing and localized small-scale soil collapse. These voids need to be promptly filled with shotcrete to keep the wall secure and prevent sinkholes from forming above. Sometimes grout needs to be injected into larger voids from up top.

Another challenge that can be encountered is hole collapse during the anchor drilling process. In most cases, after the horizontal holes are drilled, the soil stands in place so we can slide the bar in and have grout perfectly encase the bar on all sides. Any soil collapse into the hole can prevent the bar from being installed and cause poor bond and grout encapsulation. If persistent soil collapse occurs while drilling, typically the engineer will call for IBO self drilling grout injection anchors to be used. IBO anchors are self drilled into place and grout is injected through the bar, mitigating any hole collapsing concerns.

If any of these issues arise, they are carefully managed by our crew foreman and the site engineer. No extra costs will be passed along to our customer until the engineer signs off that the additional work was necessary.

We can not only help you resolve the complex troubleshooting with IBO anchors and void-filling. We can also assist with other common issues that arise during remedial work, such as:

- Secant wall leak and repair work

- Face saving measures

- Grout consolidation

- Crack repair

- Slope stabilization

- Emergency slide & shoring rehabilitation

These are just a few examples… We can work with your engineers to find solutions to existing problems, or help you foresee areas that may become problematic. And believe us, in our years of operation, we’ve seen even small issues turn into real problems if they aren’t handled correctly. That’s why it’s vital to your project to have a skilled team behind you every step of the way.

When you’re in the trenches, we’ll support your dig…

At Power Shotcrete, we have the equipment and the experience to handle any unique or specialised shoring requirements. If you require:

- strand anchors

- secant wall anchor connections

- cased hole drilling

- high hydrostatic pressure drilling with backflow preventor system

- removable anchors

- post grouting of anchors

- line drilling of existing walls

We have the unique combination of know-how and a “get it done right” attitude, where we put our best minds together to get the job done right.

Got a complex shoring project on your hands?

Need a sure-fire solution?

Contact our experts at 604-427-3301 or complete our online form.